|

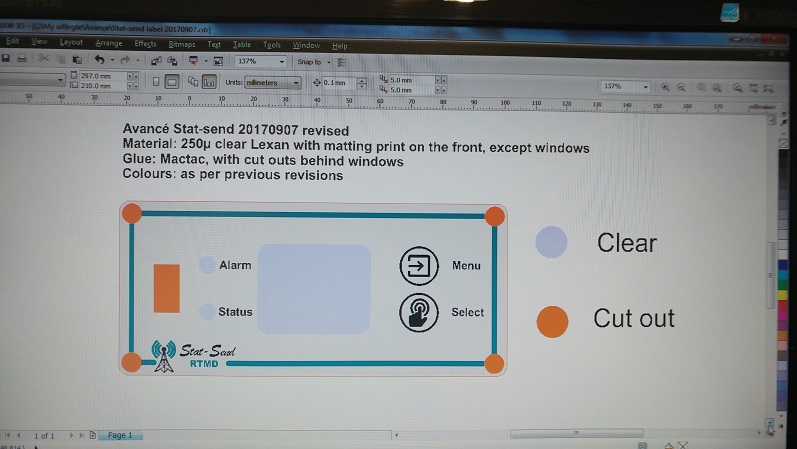

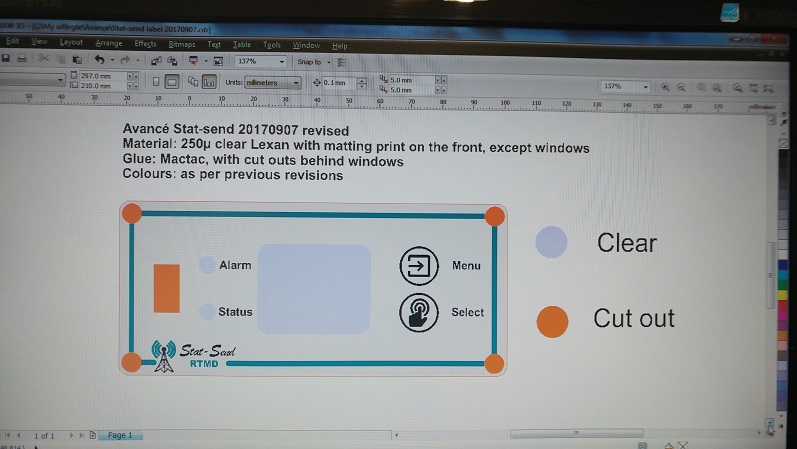

The

layout is made according to the clients specifications, using

CorelDraw. After the proof has been accepted, we do a colour

separation and send the files to have positives made

|

|

|

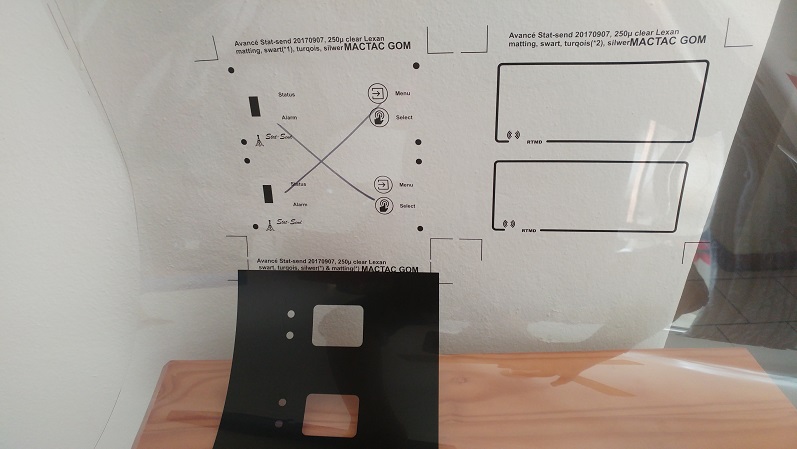

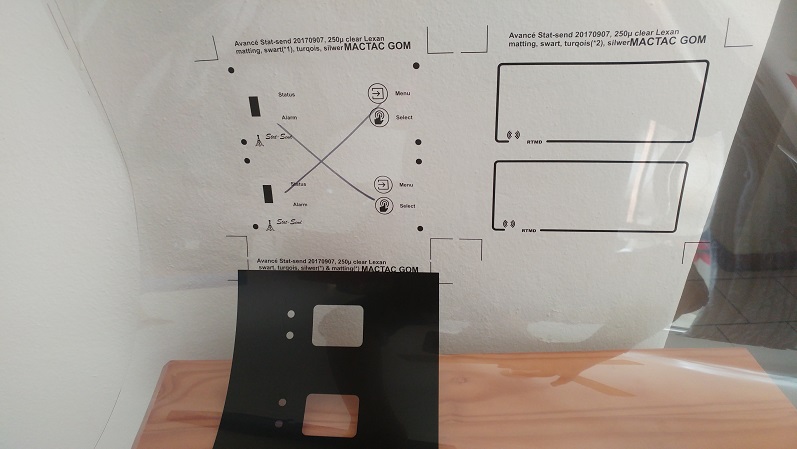

Checking

positives

|

|

|

Cleaning the

screen with special chemical products and a high pressure washer

|

|

|

When the

screen is dry, it is covered with a light sensitive photo emulsion

and left to dry in the dark room

|

|

|

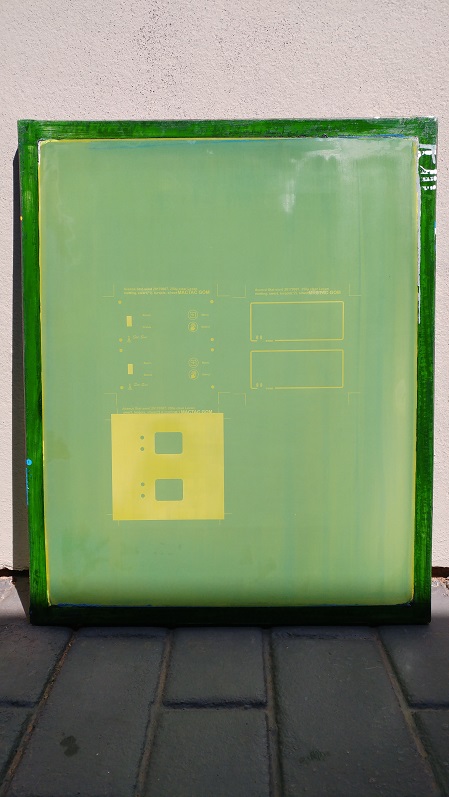

The

positive is placed between the screen and a glass table. The screen

is developed through a short exposure with high intensity light

.jpg) |

|

|

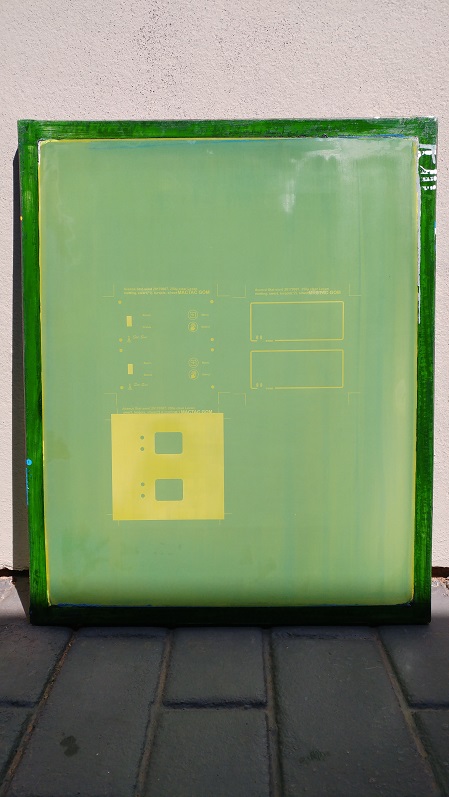

The

undeveloped parts (the image to be printed) is washed out, leaving

the image on the screen

|

|

|

The screen is

left to dry

|

|

|

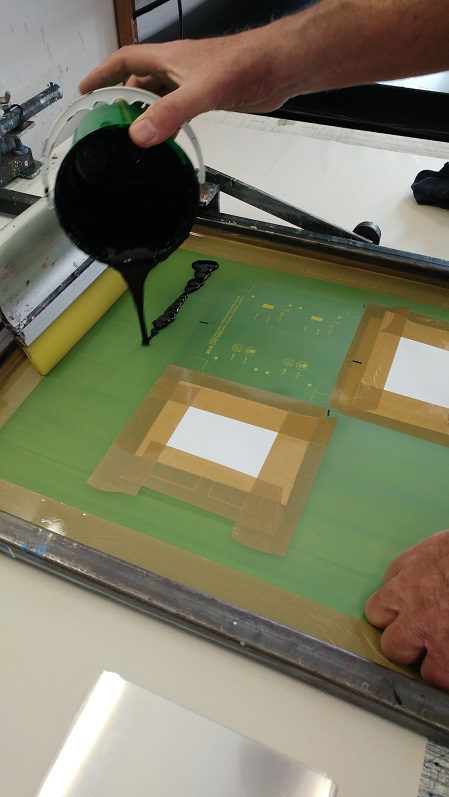

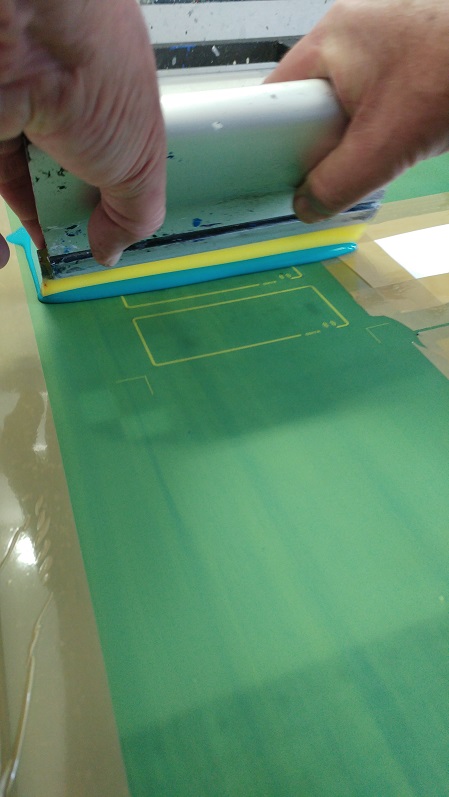

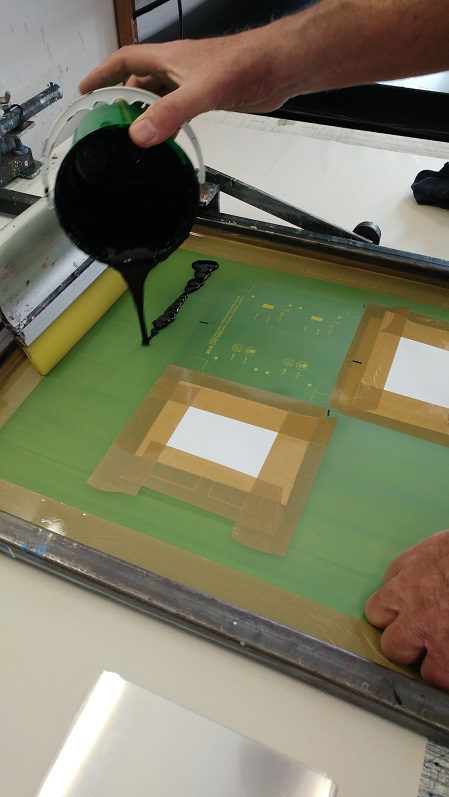

The screen is

set-up on a vacuum table, and the first colour is printed by forcing

the ink through the screen using a squeegee.

|

|

|

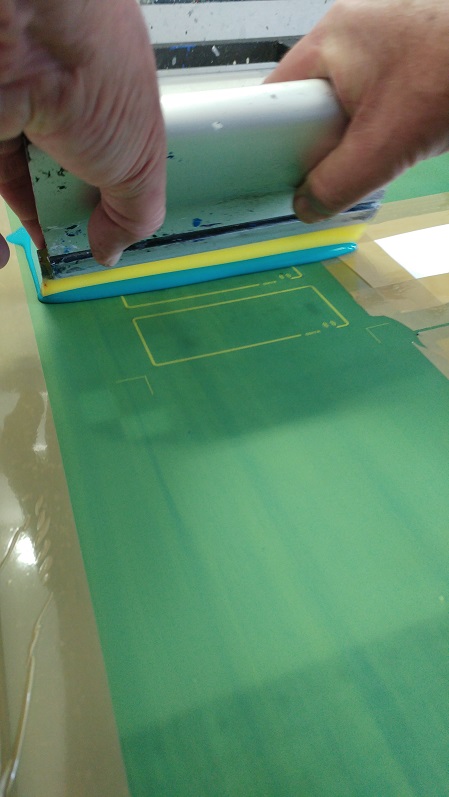

After the ink

has dried, the process is repeated for every colour

|

|

|

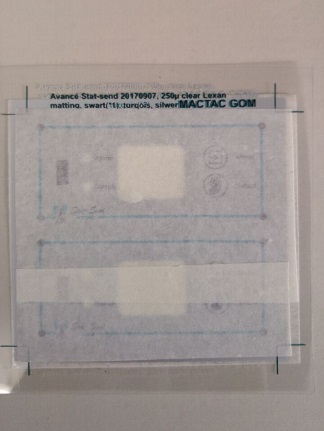

Once all the

printing is completed, it is time to apply the double sided

adhesive. If necessary, some cut-outs are made in the adhesive.

|

|

|

The adhesive is

applied

|

|

|

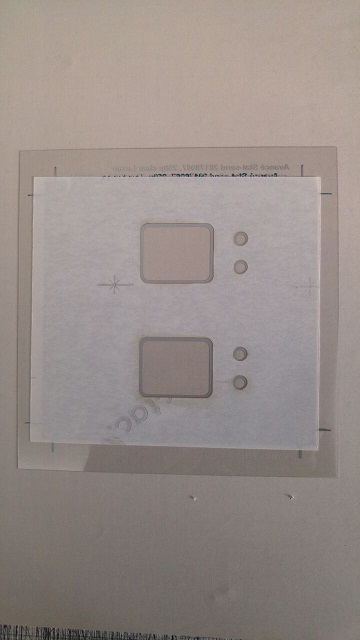

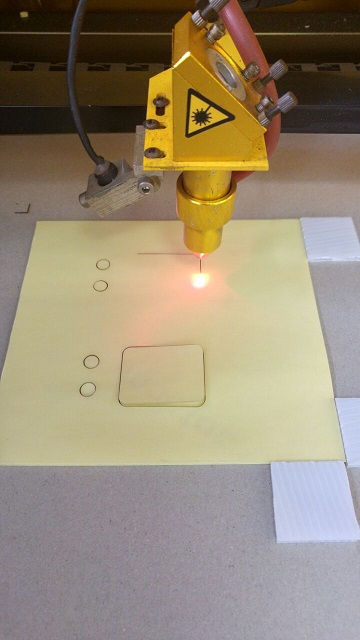

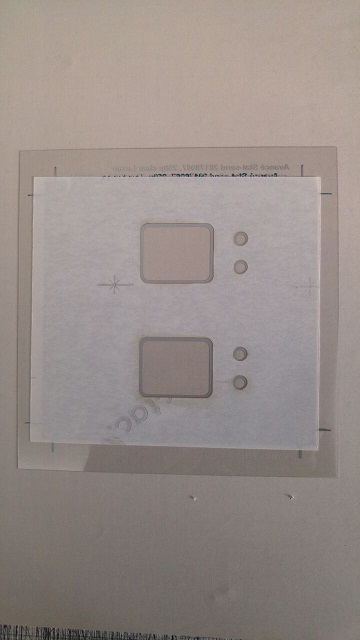

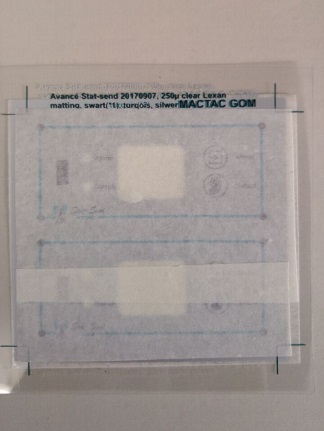

Before we do

laser cut-outs, a protective layer is applied to the front

|

|

|

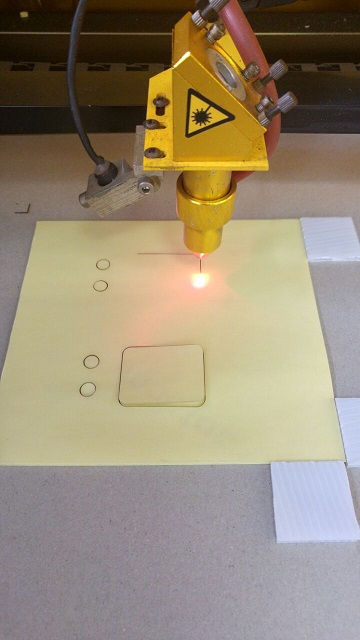

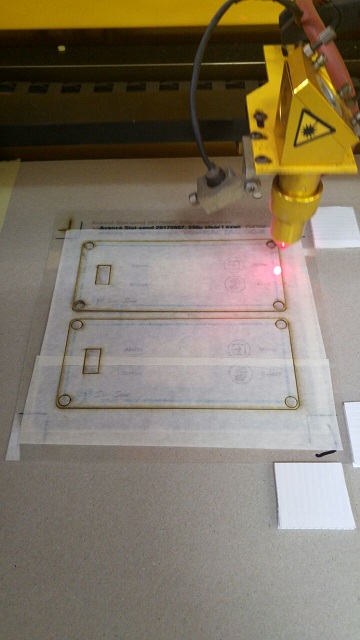

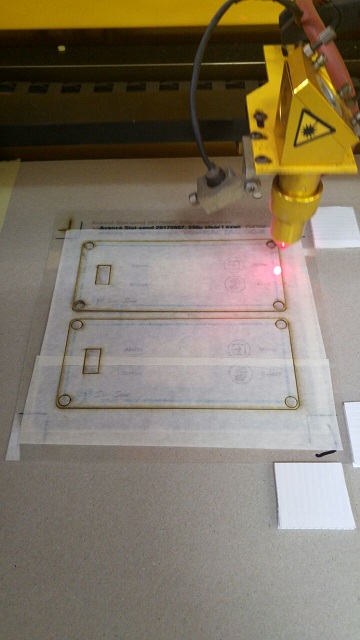

Laser cutting

|

|

|

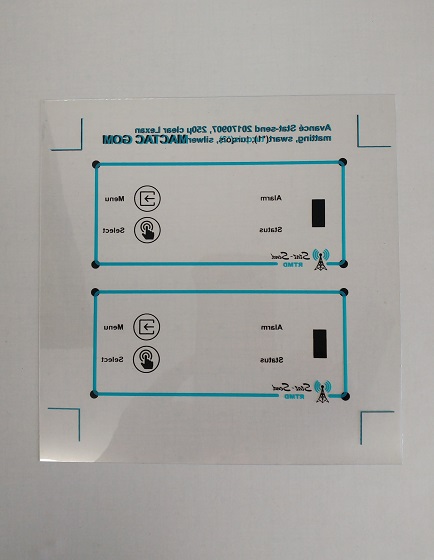

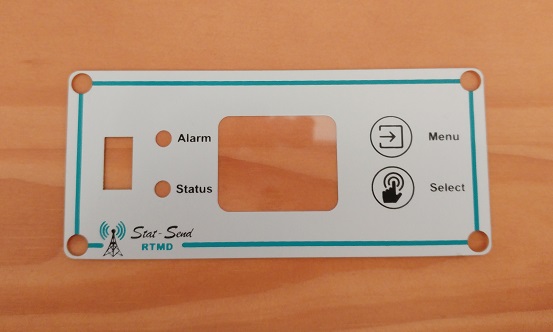

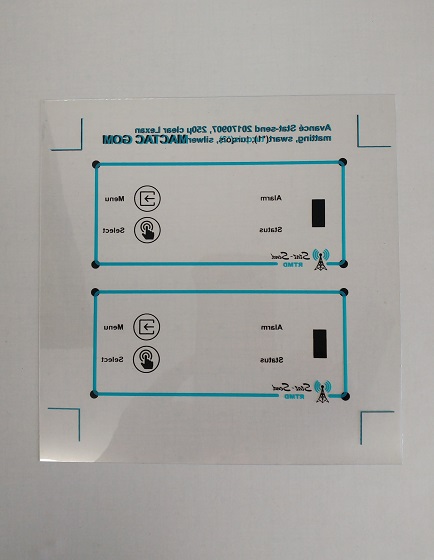

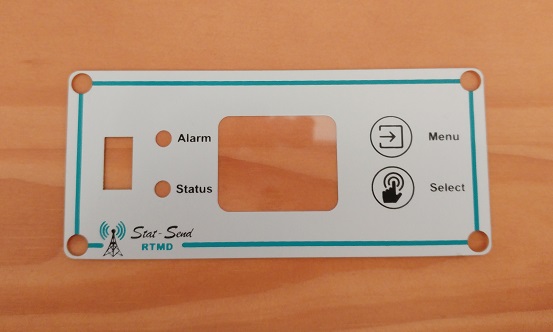

The final

product

|

|

.jpg)